Need specialized Surrey-based mold and asbestos experts right now? We quickly assess, contain, and eliminate dangerous materials using WorkSafeBC/BC OHS-approved methods, negative-pressure HEPA containment, calibrated air and moisture monitoring, and documented chain‑of‑custody sampling (PLM/TEM). We identify sources (leaks, humidity >60%), remove contaminated materials, use EPA-registered antimicrobials, and control moisture to 40-50% RH to stop recurrence. For pre-1990 suspect ACM, we execute wet methods, glove‑bag/full enclosures, and TDG‑compliant waste transport. Insurance coordination and defensible clearance included-let us explain what this means.

Key Takeaways

- Quick emergency triage in Surrey: secure utilities, establish hazard zones, set up negative-pressure containment to prevent mold amplification and asbestos disturbance.

- Accredited surveys for pre-1990 buildings: comprehensive sampling with documented chain-of-custody, laboratory PLM/TEM testing, and accurate measurement per CSA and WorkSafeBC requirements.

- Mold remediation: professional extraction of contaminated porous materials, including HEPA vacuuming, application of EPA-registered antimicrobials, and carefully controlled dehumidification to keep 40-50% RH.

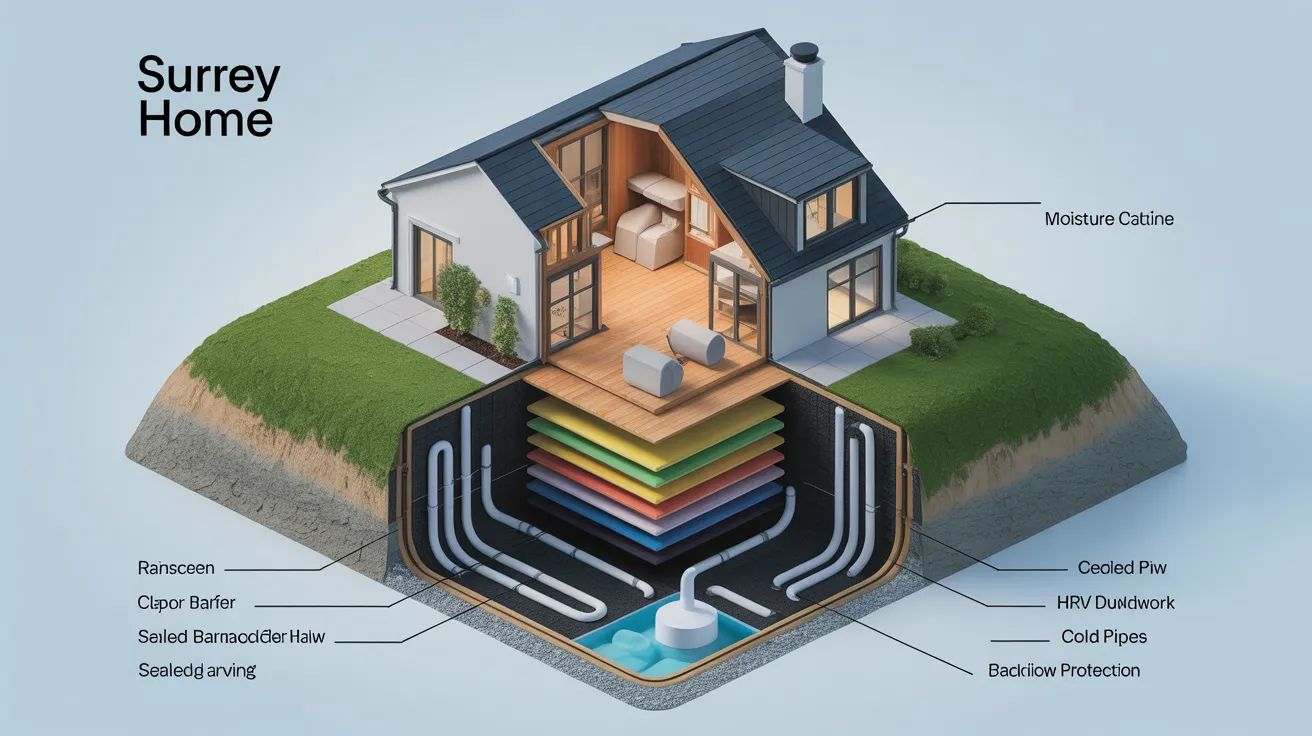

- Moisture control and prevention: resolve leak issues, implement proper grading and drainage, integrate rainscreen systems, install moisture barriers, ensure adequate insulation, integrate heat recovery ventilation, and verify proper ACH levels.

- Asbestos abatement: conducting complete containment procedures using containment methods like glove-bags and full enclosures, combined with wet procedures, HEPA extraction, proper waste transport with labeling, and comprehensive air testing before, during, and after.

Mold and Asbestos: Pressing Concerns in Surrey

Due to Surrey's humid maritime conditions, older building stock, and continuous infill development generate optimal conditions for concealed hazards, mold and asbestos require prompt attention. You deal with increased moisture content that cause mold growth in building envelopes, crawlspaces, and bathrooms, get more info while older materials often include crumbling asbestos in building materials, flooring, and textured coatings. These substances pose well-documented respiratory and carcinogenic risks, influencing local health conditions and straining healthcare resources.

There's also legal liability. WorkSafeBC regulations require hazard identification, controlled abatement, and documentation. Noncompliance results in penalties and work stoppages, and puts insurance protection at risk. Strategic assessment and proper abatement ensure occupant safety, protect property investments, and maintain timelines. You reduce lifecycle costs by eliminating structural deterioration, secondary contamination, and litigation.

Warning Signs for Professional Inspection and Testing

Even when problems appear small at the beginning, key markers in Surrey's buildings call for a certified inspection and laboratory testing. When you observe staining on drywall, ceiling panels, or foundation surfaces-particularly expanding marks or salt deposits-you should sample and verify. Lingering smells (musty, earthy, or acrid) suggest mold growth or chemical emissions; never conceal these signs-document and test. Ongoing water issues, excessive indoor humidity (>60%), or window moisture indicate conditions favorable to hidden mold. For pre-1990 structures, loose insulation, degrading ceiling surfaces, or cracked vinyl tiles suggest asbestos-containing materials; handle as dangerous until verified. If occupants report respiratory irritation, headaches, or aggravated asthma, escalate to professional air and bulk sampling compliant with WorkSafeBC and CSA standards.

Our Comprehensive Mold Remediation Protocol

Once inspection and testing identify mold, we execute a systematic, protocol-based remediation process. To begin, we document impacted surfaces, dampness origins, and transmission routes. Subsequently, we set up containment systems with pressure differential and HEPA filtration to eliminate cross-contamination. We confirm pressure differentials and airflow control with pressure gauges and smoke testing.

We prioritize source removal over encapsulation: we carefully remove and bag porous materials, then meticulously clean surfaces using wire-brushing, scraping, and HEPA vacuum processes. EPA-registered antimicrobials are applied according to substrate and contamination requirements. We address moisture concerns by drying to specific EMC targets, implementing data-logged dehumidification with balanced air circulation.

We perform cleaning beyond the containment, incorporating vents and high‑touch areas. Post‑remediation verification encompasses visual assessment, particulate analysis, and third‑party sampling as specified by regulatory guidelines or customer requirements.

Professional and Reliable Asbestos Inspection and Abatement

Even before collecting samples, you obtain a regulatory-aligned plan meeting WorkSafeBC, OHS, and EPA/AHERA protocols that defines suspect materials, containment measures, and chain‑of‑custody. We conduct inspections of various materials, implement negative pressure containment, and use appropriate protective enclosure methods determined by risk. You'll observe calibrated air monitoring pre‑work, during the process, and after completion to verify proper fiber control.

Our team collects bulk and surface samples through sanitized sampling methods, secure sampling media, and complete custody tracking. Qualified analysts conduct microscopy analysis using polarized light or TEM, and we issue reports upon analytical confirmation confirms detection limits and method accuracy. For removal procedures, we employ wet methods, HEPA‑filtered extraction, and secure waste management with sealed and identified transport containers. Final site certification includes thorough visual examination and air quality measurement standards.

Safety Regulations, Certifications, and Industry Standards We Maintain

You need assurance that qualified professionals are on site, so we hold industry-recognized certifications (including IICRC for mold, AHERA/NIOSH-aligned asbestos training) verified through current documentation. We adhere to provincial and federal requirements, including WorkSafeBC, BC OHS Regulation Part 6, and applicable federal asbestos and hazardous materials rules. We implement rigorous safety protocols-detailed hazard analysis, containment under negative pressure, air monitoring, safety-tested protective gear, and certified clearance protocols.

Industry-Recognized Certifications

While each project has its own unique characteristics, our approach to compliance stays uniform: we adhere strictly to established certifications and regulatory protocols. Our clients benefit from technicians certified to ANSI/IICRC S520 for mold remediation, including thorough containment, negative pressure, and clearance standards. Our management team possesses Asbestos Supervisor certifications, and field personnel complete hazard-awareness training conforming to current control protocols. We validate indoor air quality controls through IAQ Certification, including instrument calibration, baseline sampling, and post-cleanup validation.

Additionally, you'll find Lead Accreditation displayed on our profiles, which confirms proficiency in lead-safe work practices, dust management, and waste handling. The team's respirator fit test documentation, respirator medical clearances, and documentation trails are preserved for compliance verification. We regulate work with safety evaluation protocols, environmental monitoring, and documented training systems, ensuring your site adheres to comprehensive, evidence-based standards.

Regulatory Compliance Requirements

Because compliance is non-negotiable, our services conform to British Columbia's Workers Compensation Act and WorkSafeBC OHS Regulation (Part 5 Asbestos, Part 6 Contaminants, exposure control plans), Hazardous Waste Regulation, and BC Building Code requirements, as well as federal frameworks including the Canada Labour Code Part II, Hazardous Products Act/WHMIS 2015 (GHS), CEPA/PCB and hazardous substances provisions, and Transportation of Dangerous Goods (TDG) for waste movement. You receive auditable documentation: exposure control plans, hazard assessments, inventory logs, chain-of-custody, and TDG shipping papers. We follow Regulatory updates, implement harmonized SDS/labeling, and tune instruments per manufacturer and ISO guidance. You'll see permitting coordination with municipalities, landfill acceptance criteria verification, and defensible record retention. We also inform you of Funding programs that reduce compliance-driven abatement and disposal costs.

Thorough Safety Procedures

Even before operations begin, teams operate under a detailed safety management system that incorporates CSA, ANSI, and WorkSafeBC regulations into operational controls. You get a site-specific exposure control plan, safety analysis, and isolation strategy aligned with NIOSH and EPA standards. We verify competent supervision, fit-tested respirators, and verified air monitoring instruments as per manufacturer specifications and ISO/IEC 17025 testing standards.

You'll observe containment using negative pressure and HEPA filtration certified according to IEST standards, controlled isolation of HVAC, and controlled waste handling under TDG. We implement safety equipment requirements based on risk assessment: half- or full-face APRs, P100 filters, disposable protective wear, and decon protocols with separated clean and dirty zones. We document transfer documentation, routine clearance verification, and completion testing measured against WorkSafeBC exposure limits and post-abatement requirements.

Quick Response for Emergencies and Insurance Support

Take immediate action when water, fire, or structural damage poses a threat to indoor air quality-swift containment and source control help minimize mold growth and asbestos disturbance. You'll benefit from emergency evaluation that focuses on life safety, utility isolation, and hazard zoning, followed by negative air containment, HEPA filtration, and Category 1-3 assessment to direct material removal. Certified technicians gather verifiable moisture and particulate readings, document suspect ACM, and, where required, suspend operations for bulk sampling under safety compliance thresholds.

We quickly deploy an insurance expert who aligns scope, photos, chain-of-custody, and Xactimate estimates to match insurance policies, deductibles, and claim requirements. We facilitate adjuster walk-throughs, issue stabilization reports, and maintain compliance logs. You get clear timelines, cost transparency, and documented, standards-driven mitigation that helps secure claim authorization.

Long‑Term Moisture Control and Prevention Methods

While rapid intervention manages pressing issues, durable outcomes hinge on addressing moisture problems and stopping pathways that enable mold development and asbestos exposure. You'll need to implement a layered strategy: improve surface drainage, isolate foundation access points, and maintain water barrier systems. Use ongoing moisture tracking to sustain interior RH between 40-50%; connect smart sensors with warnings and performance monitoring. Deploy balanced ventilation and HRVs, verify ACH through air exchange verification, and reinforce ductwork. Place suitable vapor barriers on the warm-in-winter side following BCBC guidance; pair with exterior rain screens and capillary breaks. Insulate cold surfaces to prevent condensation. Install sump systems with backflow protection. Record setpoints, service intervals, and chain-of-custody for records. Review controls quarterly and after renovations.

FAQ

Understanding Our Warranties and Service Guarantees Post-Remediation

The warranty protection encompasses designated areas post-remediation, with warranty terms dependent on source correction and compliance with IICRC S520 protocols. We provide complete documentation, clearance testing, and planned follow-up visits to verify no regrowth and compliance. If conditions recur within the warranty timeframe and the original issue was resolved, you'll get no-cost reinspection and targeted retreatment. Coverage doesn't include new water intrusions or altered conditions. You can request independent validation to maintain regulatory defensibility.

What Payment Plans and Financing Options Do We Offer for Large Projects?

We provide numerous payment options that are both compliant and transparent. We offer financing with fixed APRs including no prepayment penalties and clear amortization schedules. We support staged draws connected to construction checkpoints, along with bank transfers and card processing, and HCSA/FSA where applicable. We complete detailed validation of personal details, earnings, and work specifications, maintain full regulatory compliance, and provide electronic signing options. Decisions on pre-approval typically come within minutes, pending complete review.

Will We Need to Vacate, and for How Long During Work?

You will likely need to vacate during remediation work. For asbestos, safety guidelines mandate full containment, negative pressure, and clearance air testing; anticipate relocation lasting 1-3 days for minor affected spaces, 3-7+ days for extensive remediation. For mold, IICRC S520 calls for proper containment with HEPA cleaning; you may remain if the work zone is properly sealed, but temporary relocation should be considered for sensitive individuals. Length of work depends on square footage, affected materials, and laboratory testing timeframes.

How Are Pets and Personal Items Protected During the Remediation Process?

We secure your pets and valuable items by implementing isolated work zones, moving pets to safety, and storing items securely. Think of it as a professionally coordinated beehive move - organized and contained. We coordinate pet relocation to off-site care facilities or a sealed safe room with advanced HEPA filtering. For possession safeguarding, we properly contain non-porous goods, dispose of affected porous objects, and record detailed chain-of-custody. Our certified technicians comply with EPA/OSHA and IICRC S520 standards: implementing negative pressure, establishing polypropylene barriers, building decontamination chambers, and confirming proper air changes before authorizing return.

Can You Coordinate Required Permits and Strata Approvals on Our Behalf?

Absolutely. We take care of regulatory compliance and strata coordination throughout the entire process. We assess requirements, identify relevant regulations, and develop required paperwork (drawings, MSDS, abatement plans). We acquire required authorizations, schedule necessary inspections, and maintain audit-ready documentation. For strata, we ensure bylaw compliance, provide required notifications, attend council meetings, and get documented permissions. We provide you with a detailed schedule, regular updates, and approvals, guaranteeing regulatory adherence, reduced interference, and thorough project documentation.

Conclusion

Safeguard your compliance, health, and property. If you discover signs of water damage, discoloration, or suspicious substances, book testing and remediation before small concerns become significant challenges. Our team follows CSA, IICRC S520, and WorkSafeBC guidelines, utilizing negative pressure and HEPA filtration, while maintaining detailed records of every step for insurance purposes. You'll receive rapid assistance, verified chain-of-custody lab results, and detailed post-remediation verification. Stay protected through proper moisture control, enhanced ventilation systems, and regular inspections-ensuring problems don't resurface.